Leading the way with Lasers !

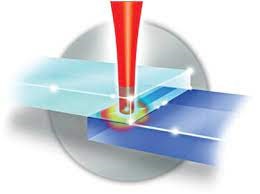

An Automotive Tier 1 leader in the Indian and global market encountered challenges in the manufacture of an optoelectronic component to be supplied to vehicles. While their strong R&D team was able to design the component with an innovative ground up approach, they faced challenges in hermetically packaging the same. Coemtek was able to work with the customer and prove out this application using laser welding and is pleased to share news of securing an order for the same. This is just one of many examples of how the team at Coemtek was able to work with a motivated customer to develop a successful solution.

Leaving your mark on the part !

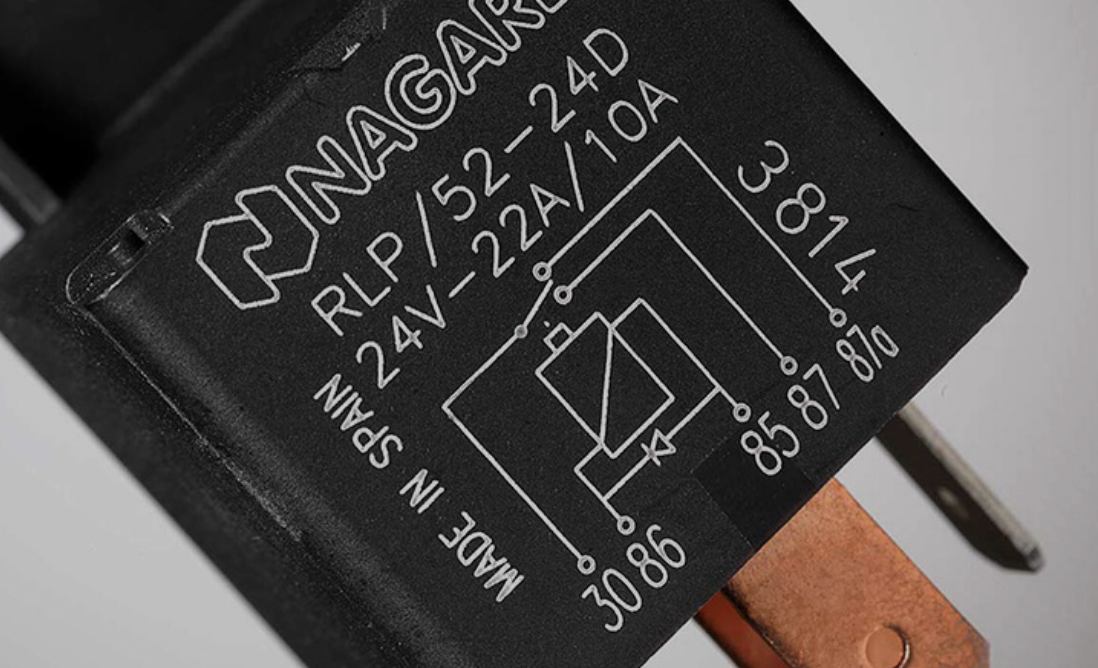

A leading manufacturer of electro-mechanical relays and switches was looking for a reliable solution to address their critical marking needs on the plastic housing. The laser marking solution was also required to be compatible with a sophisticated automation system. Coemtek was able to step up to the challenge, design and implement a solution, at the speed and price point required by the Customer. Our choice of lasers for this case was UV based, resulting in clear marking across a range of plastic components with different colors. Needless to say that this happy customer has rewarded us with more orders

Flexibility….meet Performance !

Automotive Tier customers are facing challenges in development of custom machines that offer productivity and performance while providing flexibility in the types of products that the machine can make. Coemtek, took up the challenge to conceptualize develop and prove a highly flexible ultrasonic work cell for manufacture of auto motive liner for an innovative tier 1 manufacturer. The project was very demanding as this is the first of its kind. We are grateful to the customer for providing the time and were reminded of the adage “ All good things for those who wait” We are interested and motivated to take this flexible work cell concept further into development of SPM’S for other segments.

Never too hot to handle !

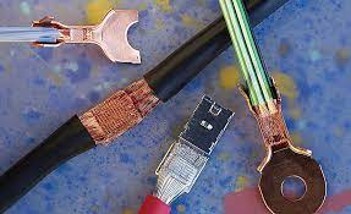

The rapid development of EV’s have created a large need for joining technologies that can result in low resistance connections to avoid excessive heating and losses from the flow of significant current through these cables and connectors. Coemtek worked with an automotive EV customer to develop a connection based on ultrasonic metal joining technology to successfully provide a solution. We welcome any applications that have such needs for metal welding in the EV and non EV space.

Do you see what I see ?

With 24/7 production cycles, it is impossible for manual visual inspection to intervene in a timely manner to protect expensive tools and equipment from damage. This was the case with one of our reputed customers leading the Automotive Tier 2 space. The maintenance department was struggling with potential breakdowns and brainstormed with our engineers on a possible solution. We are happy to share that strong collaboration with the customer has resulted in the successful deployment of an automated AI based vision inspection solution. AI helped the systems learn new modes of failure quickly and was able to catch 100% of the defects with just 24 hours of training. The customer has given us the opportunity to deploy this solution in all their machines ! Please contact. Us to learn more about our unique solutions in this space.